Range of application

Cross-section, polish, lamella or surface coating, from carbide sample to butterfly wing - JEOL preparation solutions are capable of overcoming even the most challenging of problems! Thanks to the fast yet careful cutting, samples are optimally prepared for perfect, artifact-free analysis. For each specific need, JEOL offers a tailor-made combination of preparation and microscopy systems.

Solutions

- Suitable for every sample type: be that hard diamond or soft butterfly wing

- Patented solutions for artifact-free preparation

- User-friendly operation and high degree of automation

- Ideal addition to your high-end microscopy system

Detailed solutions

- Analysing abrasive materials

Analysing abrasive materials

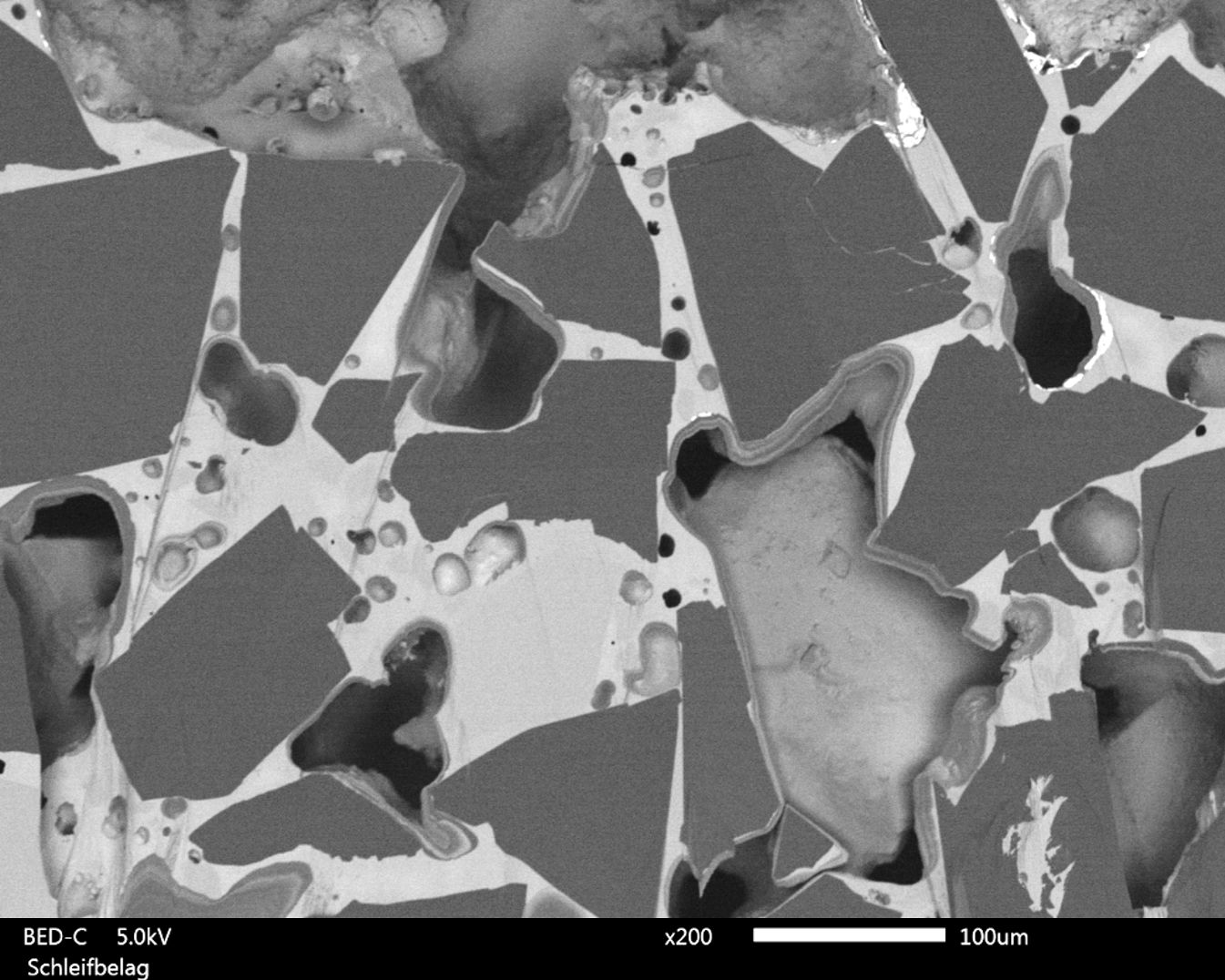

Abrasives contain particles of very hard, ceramic grains. Mechanically stripping the material structure to evaluate the corn and pore distribution is therefore very challenging. JEOL systems enable the simple, artifact-free production of large-scale cross-sections for examination.

Product groups

Preparation Systems

Solutions

Cross-section through an abrasive material with boron nitride grains

Cross-section through an abrasive material with boron nitride grainsCross-section through an abrasive material with boron nitride grains

Source data: JEOL (Germany) GmbH, Diamant-Gesellschaft Tesch GmbH, data authorised for publication

- Analysing paint defects

Analysing paint defects

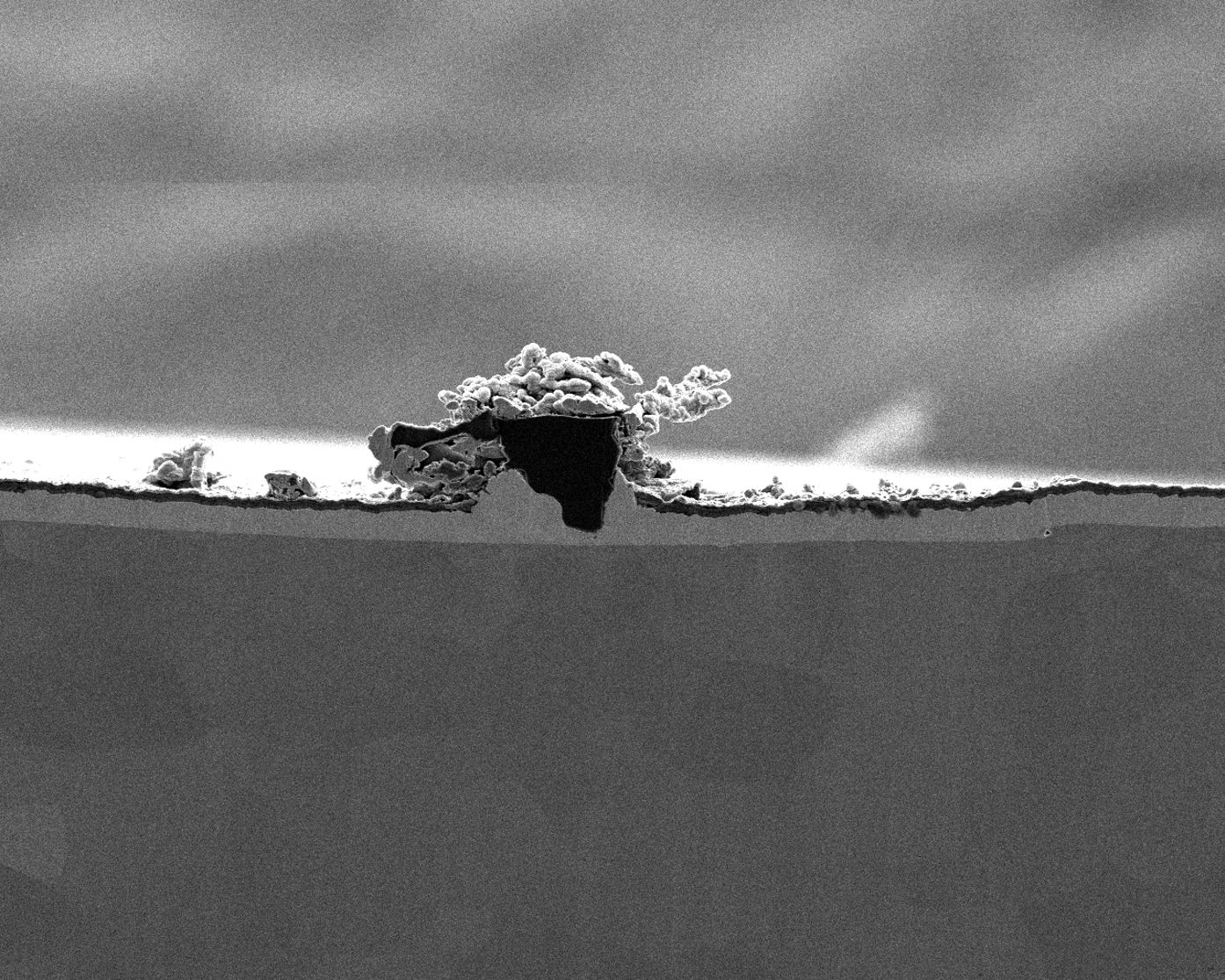

Modern paintwork is usually performed as a multi-layer system. In the case of macroscopically visible paint defects, it is very important to be able to determine the layer in which the cause of the defect lies. Our systems make it easy to examine the cross-section of the layers of paint.

Product groups

Preparation Systems

Solutions

Cross-section of a painted metal surface. The diameter of the inclusion is approx. 10 µm.

Cross-section of a painted metal surface. The diameter of the inclusion is approx. 10 µm.Cross-section of a painted metal surface. The diameter of the inclusion is approx. 10 µm.

Source data: JEOL Ltd. / CP brochure

- Analysing paper

Analysing paper

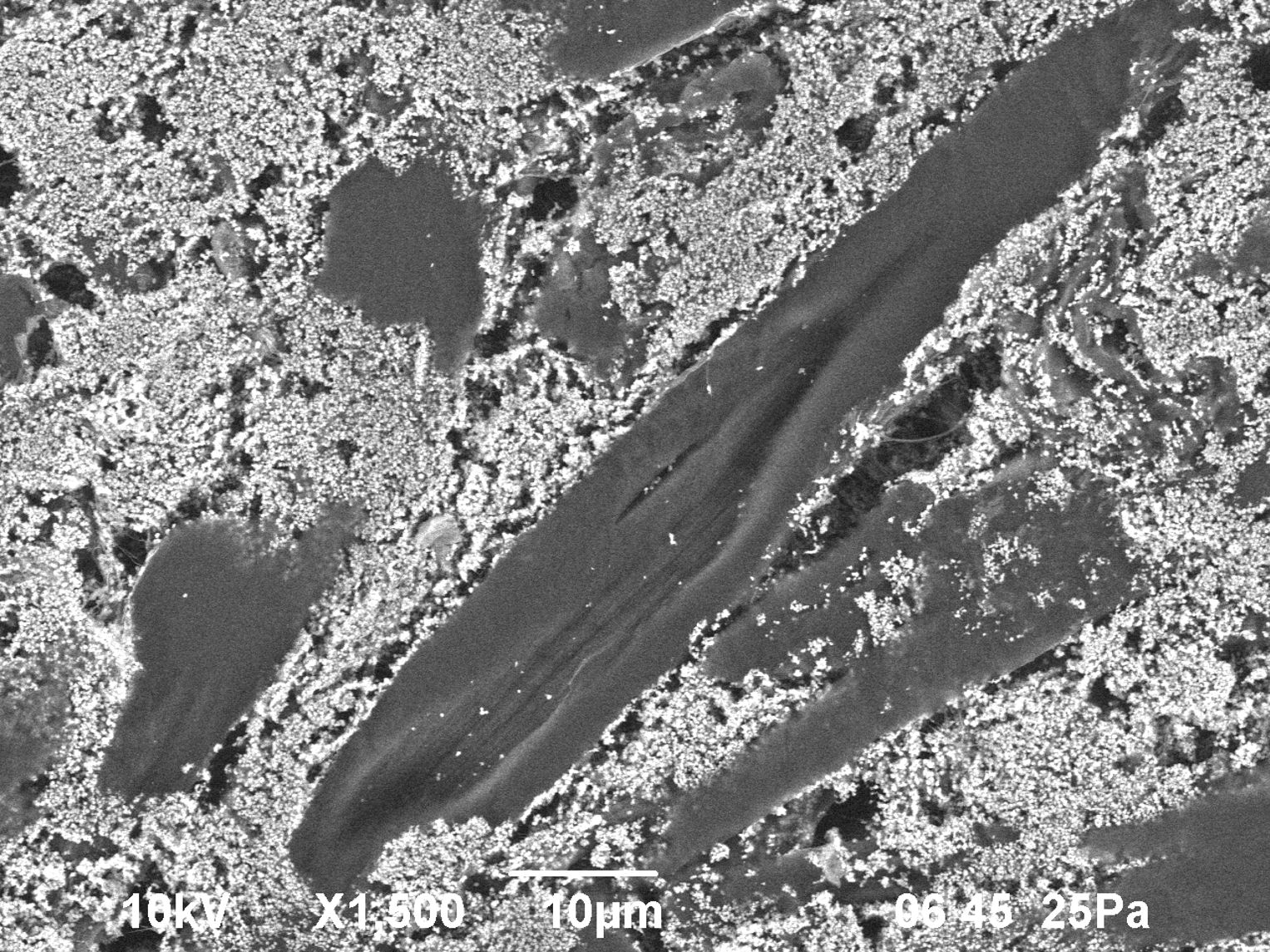

As a mass-produced product, it is possible to manufacture paper cost effectively if the ratio of fibres and filler material is optimised without the changing the mechanical and printing properties. In this respect it is important to examine the distribution of fibre and filler material in the paper both during the paper development and production. The exceptionally robust analytic systems from JEOL can be used during challenging routine operation for artifact-free preparation, as well as for the precise morphological and chemical characterisation of cellulose.

Product groups

Preparation Systems

Solutions

Facing cut through a sheet of paper

Facing cut through a sheet of paperFacing cut through a sheet of paper

Source data: JEOL (Germany) GmbH

- Characterising cryostabilised samples

Characterising cryostabilised samples

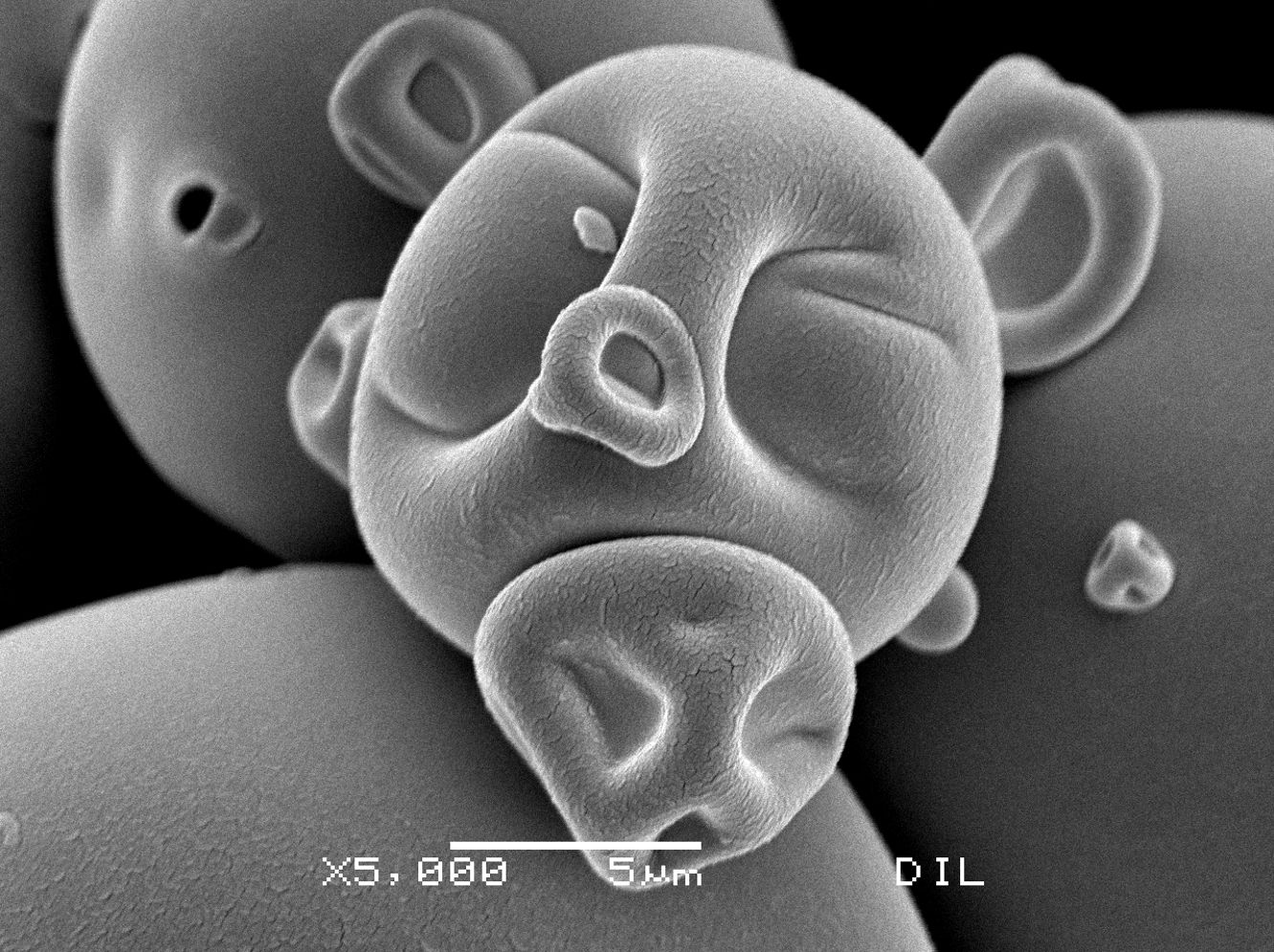

Specific preparation methods must be used for the high-resolution imaging and analysis of biological samples in an electron microscope. Food stuffs and their constituents in particular can only be imaged artifact-free through active cooling. JEOL electron microscopes are therefore prepared as standard for the installation of cryogenic systems so that sensitive samples can be prepared externally, transferred in a cooled state and subsequently examined in a cryogenic mode of operation.

Product groups

Preparation Systems

Solutions

Electron microscope image of powdered milk

Electron microscope image of powdered milkElectron microscope image of powdered milk

Source data: JEOL (Germany) GmbH, DIL Quakenbrück

- Characterising layer defects

Characterising layer defects

Modern paintwork is usually a multi-layer system. In the case of macroscopically visible paint defects, it is very important to be able to determine the layer in which the cause of the defect lies. JEOL preparation systems enable the simple and reproducible production of artifact-free cross-sections.

Product groups

Preparation Systems

Solutions

Cross-section of a painted metal surface. The diameter of the inclusion is approx. 10 µm.

Cross-section of a painted metal surface. The diameter of the inclusion is approx. 10 µm.Cross-section of a painted metal surface. The diameter of the inclusion is approx. 10 µm.

Source data: JEOL Ltd., CP brochure

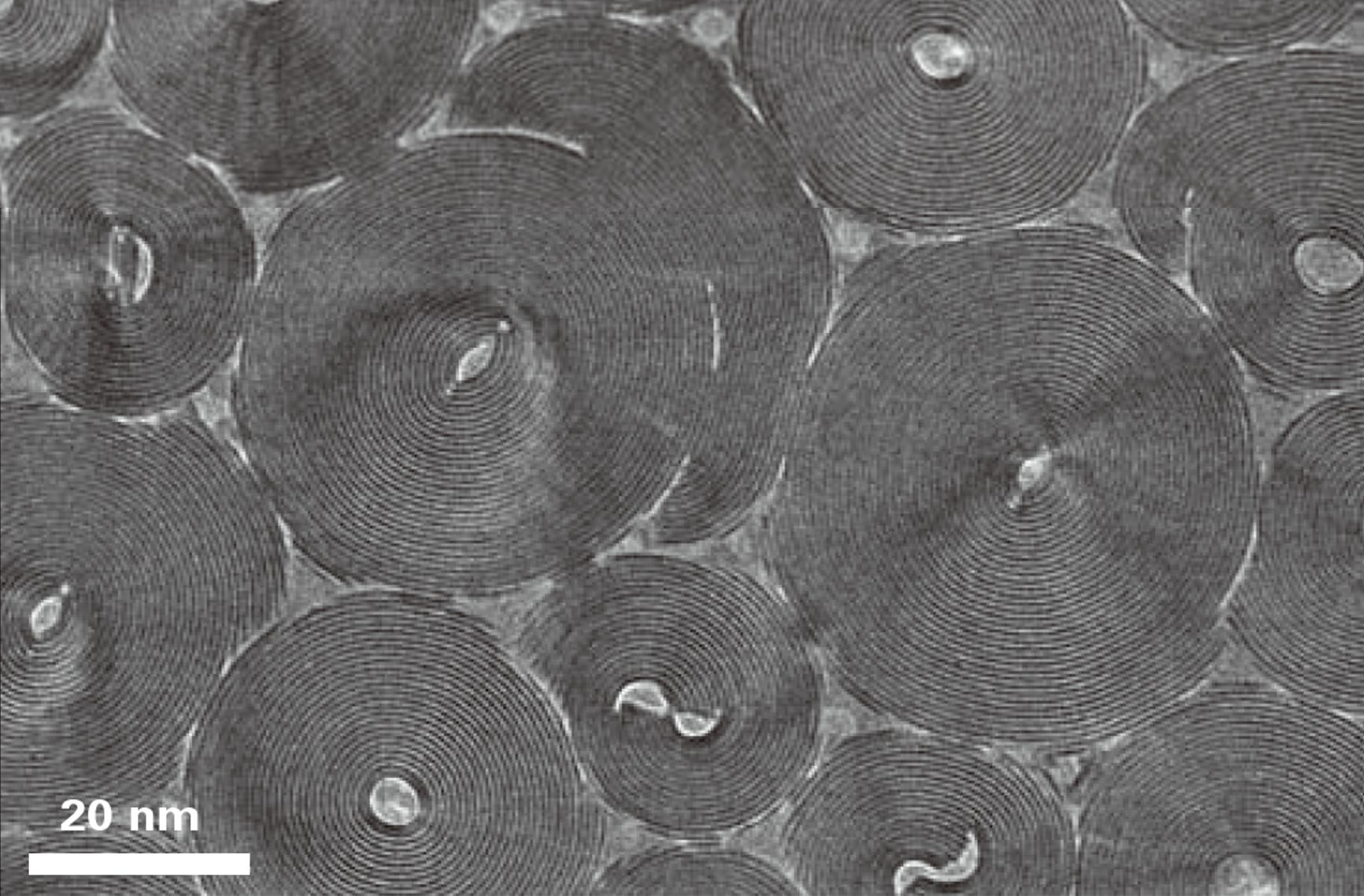

- Characterising powders

Characterising powders

Metal powders are used for producing metal ceramics, among other things, with the density and structure of the powder playing an important role. With JEOL microscopes it is possible to image the structure and material composition down to the last detail. JEOL supplies an established and powerful complete solution for simple, artifact-free preparation and high-resolution imaging and analytics.

Product groups

Preparation Systems

Solutions

SEM image of a metallic powder

SEM image of a metallic powderSEM image of a metallic powder

Source: JEOL (Germany) GmbH

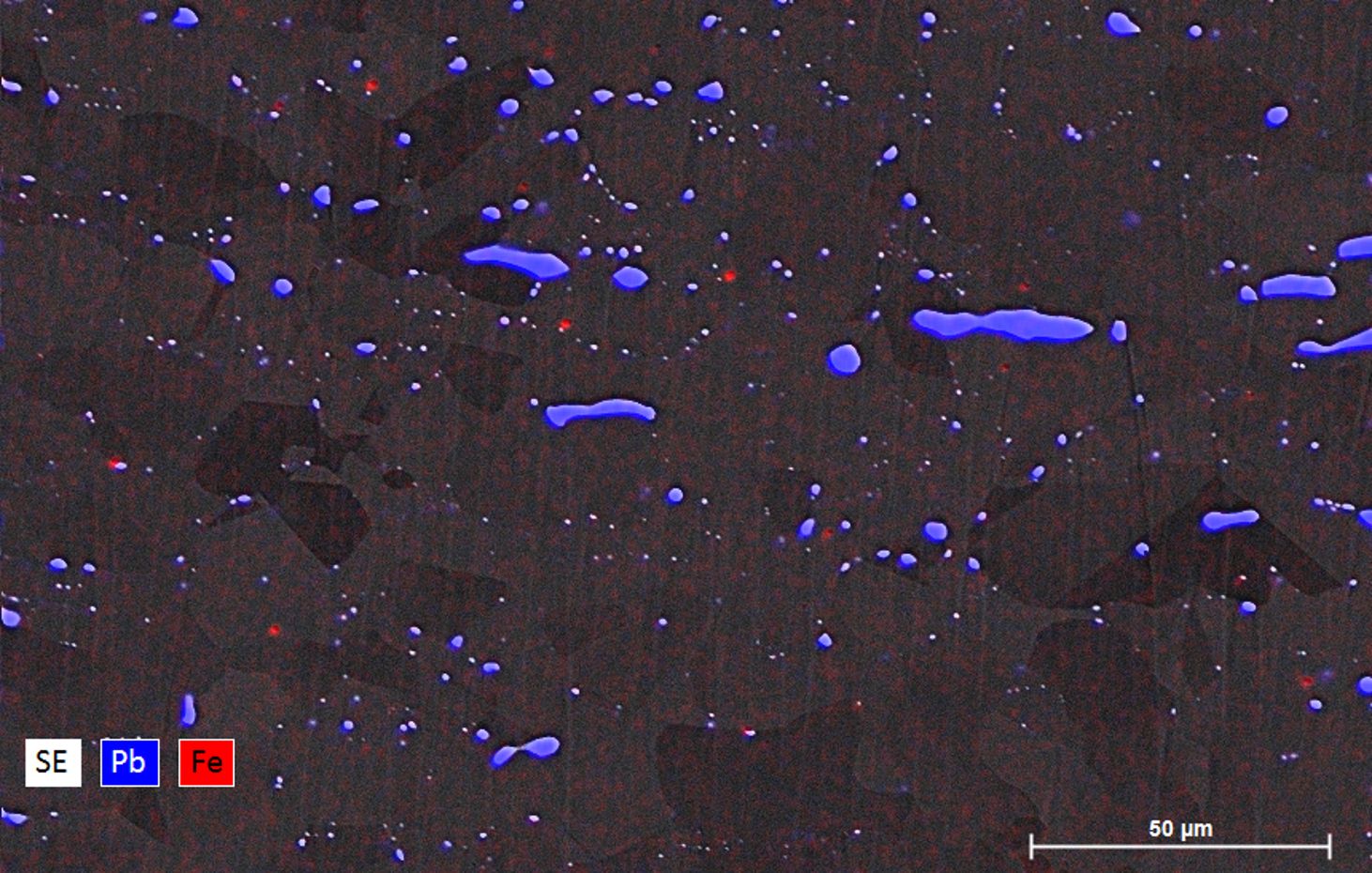

- Characterising precipitates

Characterising precipitates

The formation of precipitates is used systematically to define the mechanical properties of a metallic structure. However, as a form of contamination, these can also be undesired. In order to be able to judge the quality of an alloy, it is necessary to determine the morphology and chemical composition of the precipitates. This is why JEOL supplies all-round, complete solutions, from artifact-free sample preparation to high-resolution analysis from the µm to the nm level.

Product groups

Preparation Systems

Solutions

Element mapping image of a brass alloy

Element mapping image of a brass alloyElement mapping image of a brass alloy

Source data: JEOL (Germany) GmbH

- Fibre analysis

Fibre analysis

Fibres are used in many branches of industry, e.g. in textile processing or as a structural material in mechanical engineering. Their structural properties can be studied by means of a fibre cross-section, for example. JEOL supplies an established and powerful complete solution for simple, artifact-free preparation and high-resolution imaging and analytics.

Product groups

Preparation Systems

Solutions

SEM image of a cross-section through a fibre bundle

SEM image of a cross-section through a fibre bundleSEM image of a cross-section through a fibre bundle

Source data: JEOL Ltd., Ion Slicer brochure

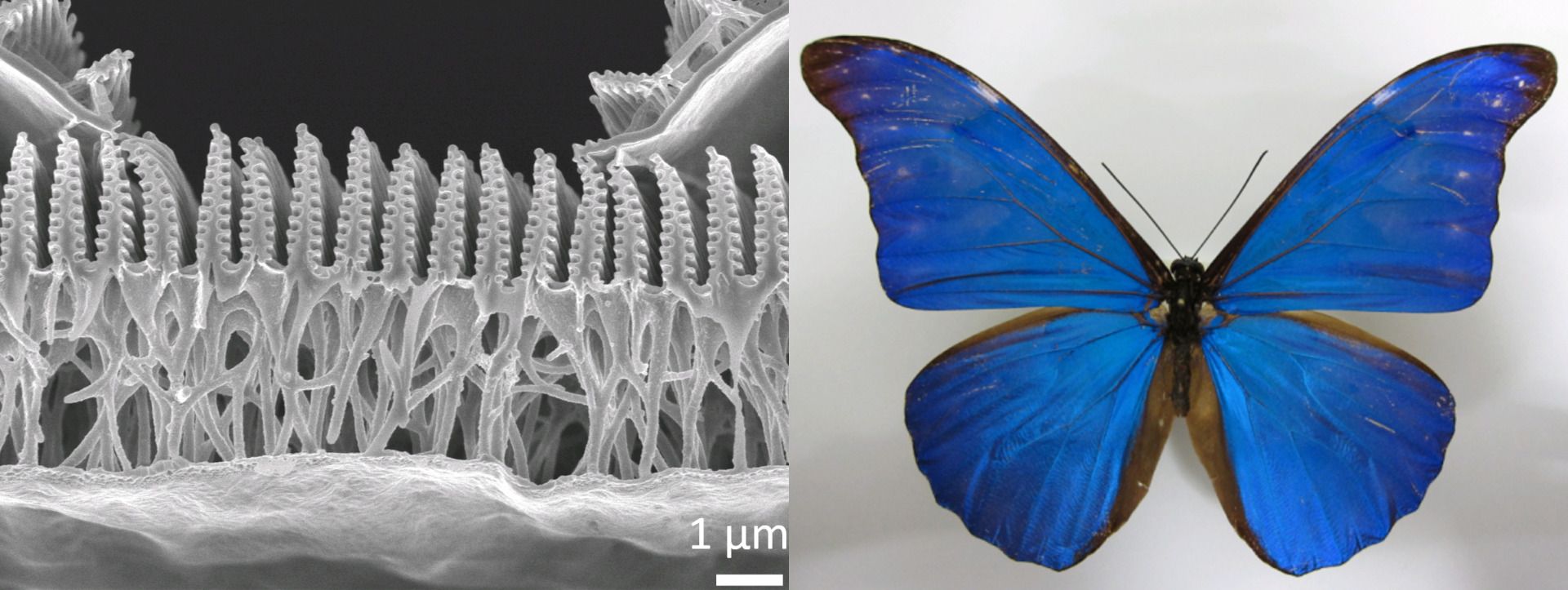

- Preparation and characterisation of fragile structures

Preparation and characterisation of fragile structures

The colours of a butterfly wing are created by pigment or structural colours. Due to the delicate surface of the wing, it is mechanically impossible to prepare a cross-section. With JEOL preparation systems and scanning electron microscopes, even fragile, organic structures can become accessible and visible.

Product groups

Preparation Systems

Solutions

Image of a cross-section through a butterfly wing (Morpho)

Image of a cross-section through a butterfly wing (Morpho)Image of a cross-section through a butterfly wing (Morpho)

Source data: JEOL Ltd., Cross Section Polisher brochure

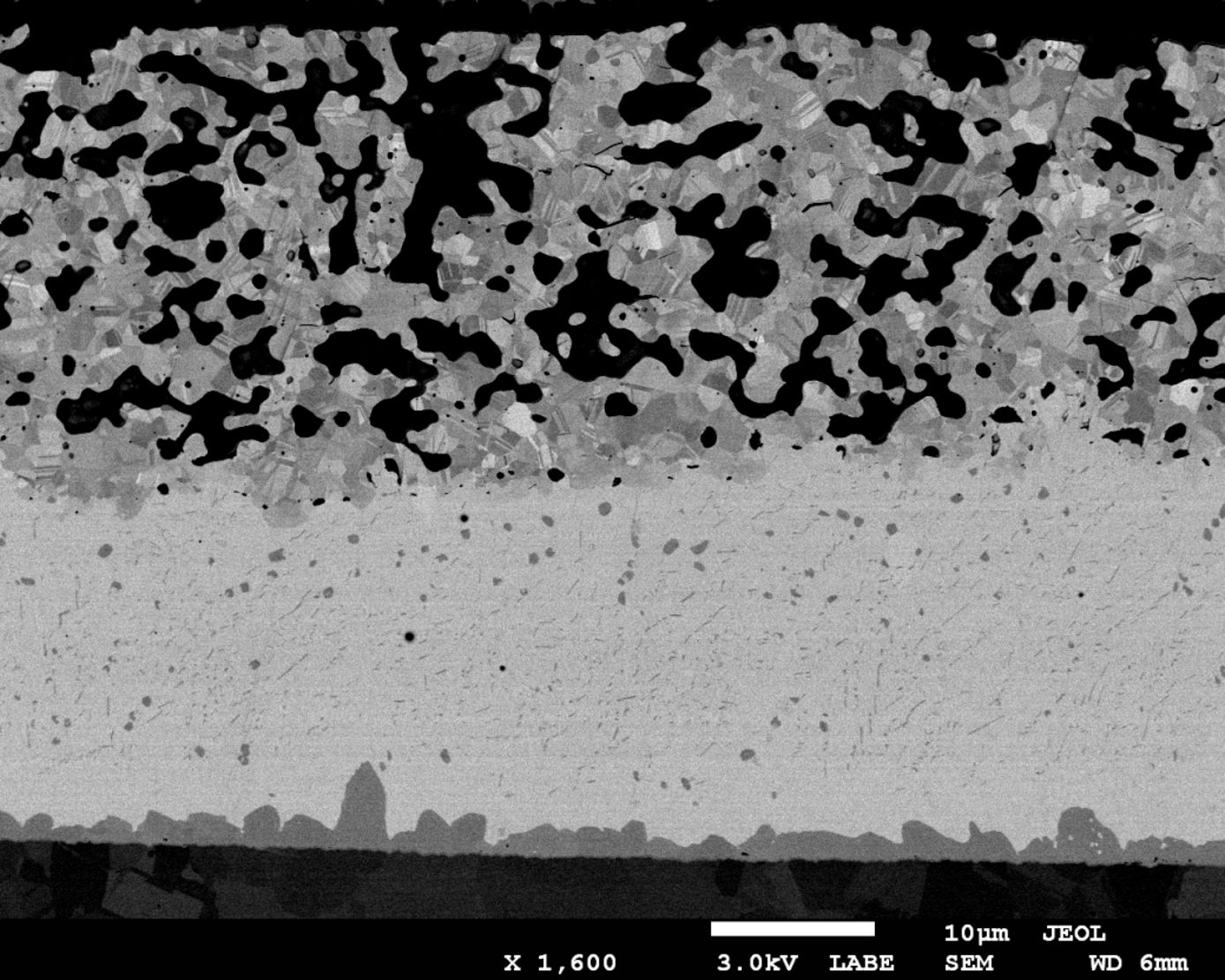

- Quality assurance of coating systems

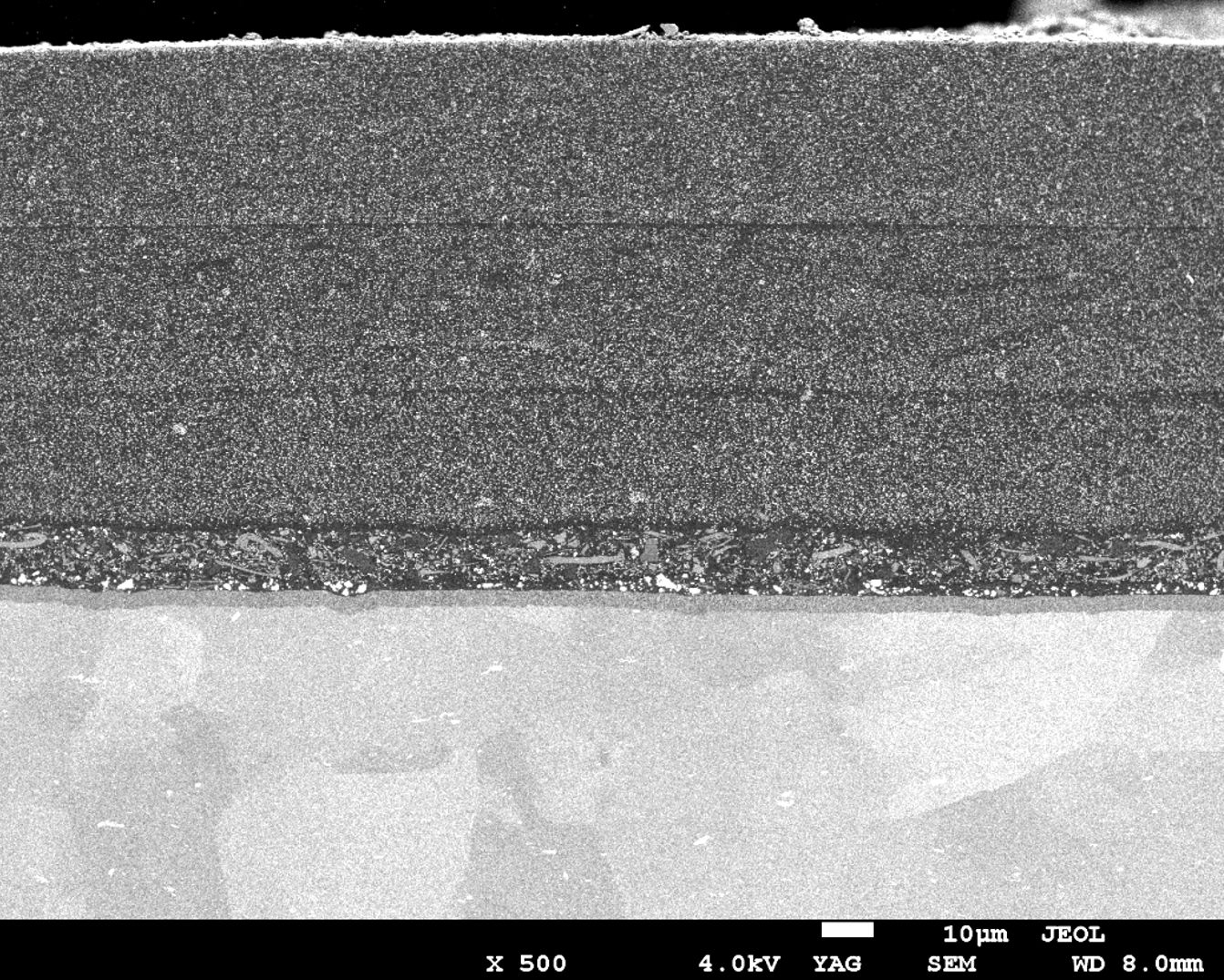

Quality assurance of coating systems

Many of today's material systems are being functionalised. Tailor-made properties, such as abrasion resistance, colour or chemical resistance, are achieved by forming multi-layer systems on substrates. The systems manufactured by JEOL simplify the examination of these coating systems. JEOL supplies complete solutions from artifact-free preparation to automated and reproducible extraction of relevant parameters such as layer thickness or roughness.

Product groups

Preparation Systems

Solutions

Coating system on a metallic substrate

Coating system on a metallic substrateCoating system on a metallic substrate

Source data: JEOL (Germany) GmbH

- Structur analysis of multi-layer systems

Structur analysis of multi-layer systems

For functionalised high-performance materials, the need for the controlled application of multi-layer systems on a substrate is becoming increasingly important. Specifically in the context of protective layers on metallic substrates, these systems make an important contribution to improving the longevity of heavily stressed components. In order to be able to image the chemical composition and the microstructural properties, JEOL has developed instruments that make it possible to prepare multi-layered components and map them to a previously unavailable depth of detail.

Product groups

Preparation Systems

Solutions

Layers of paint on an Al substrate

Layers of paint on an Al substrateLayers of paint on an Al substrate

Source: JEOL (Germany) GmbH

- Structure / cross-section of electronic components

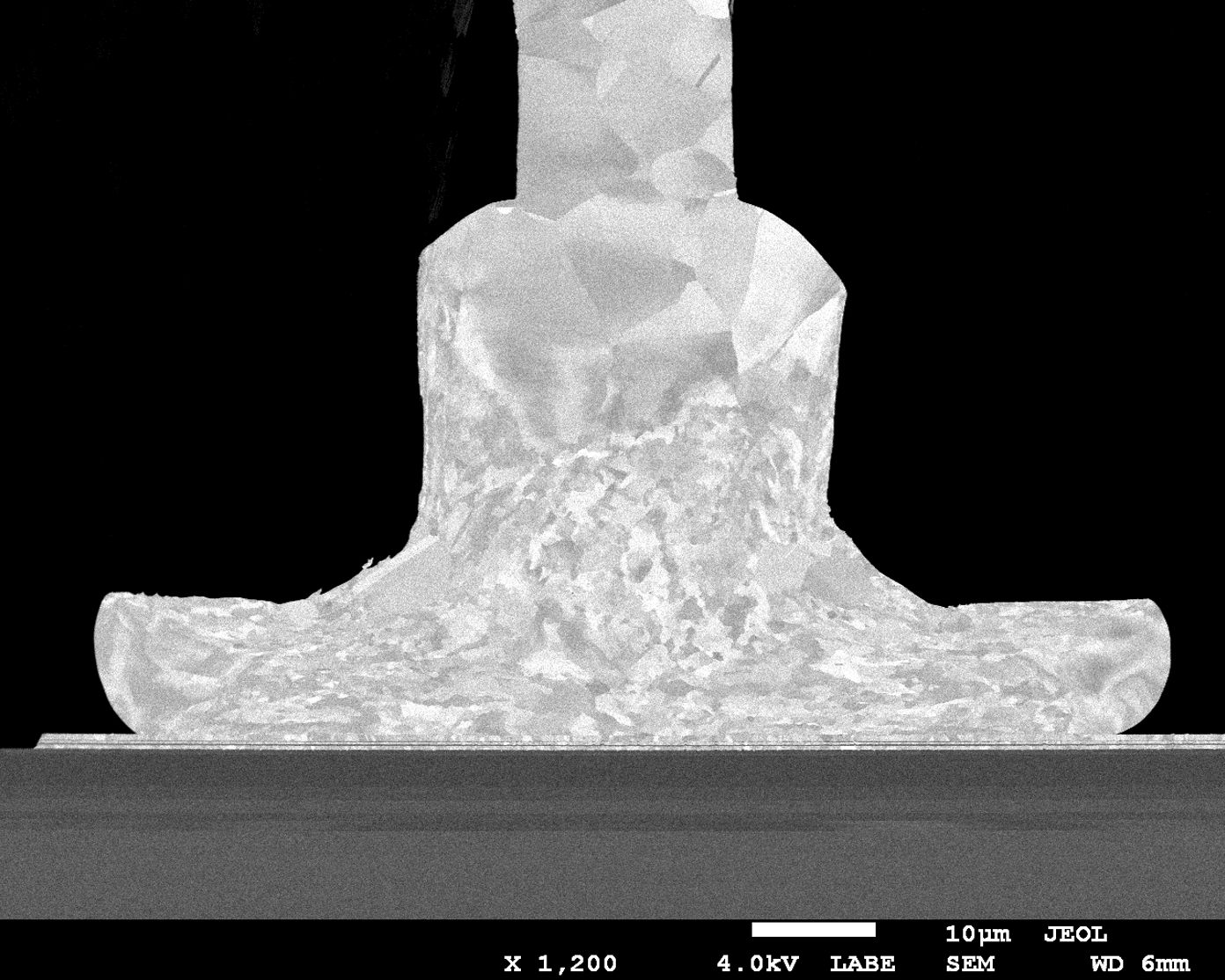

Structure / cross-section of electronic components

In the electronics industry, integrated circuits and components have to be connected by wires. The failure of this interface is one of the commonest causes of failure of these components. Characterising the quality of this interface requires pinpoint-accurate cross-sectional preparation without any thermomechanical load on the wire. JEOL systems enable the quick, simple, artifact-free and pinpoint-accurate preparation and detailed characterisation of this interface.

Product groups

Preparation Systems

Solutions

Cross-section through the bond pad of a light emitting diode.

Cross-section through the bond pad of a light emitting diode.Cross-section through the bond pad of a light emitting diode.

Source data: JEOL (Germany) GmbH

- Texture and element mapping of metallic materials

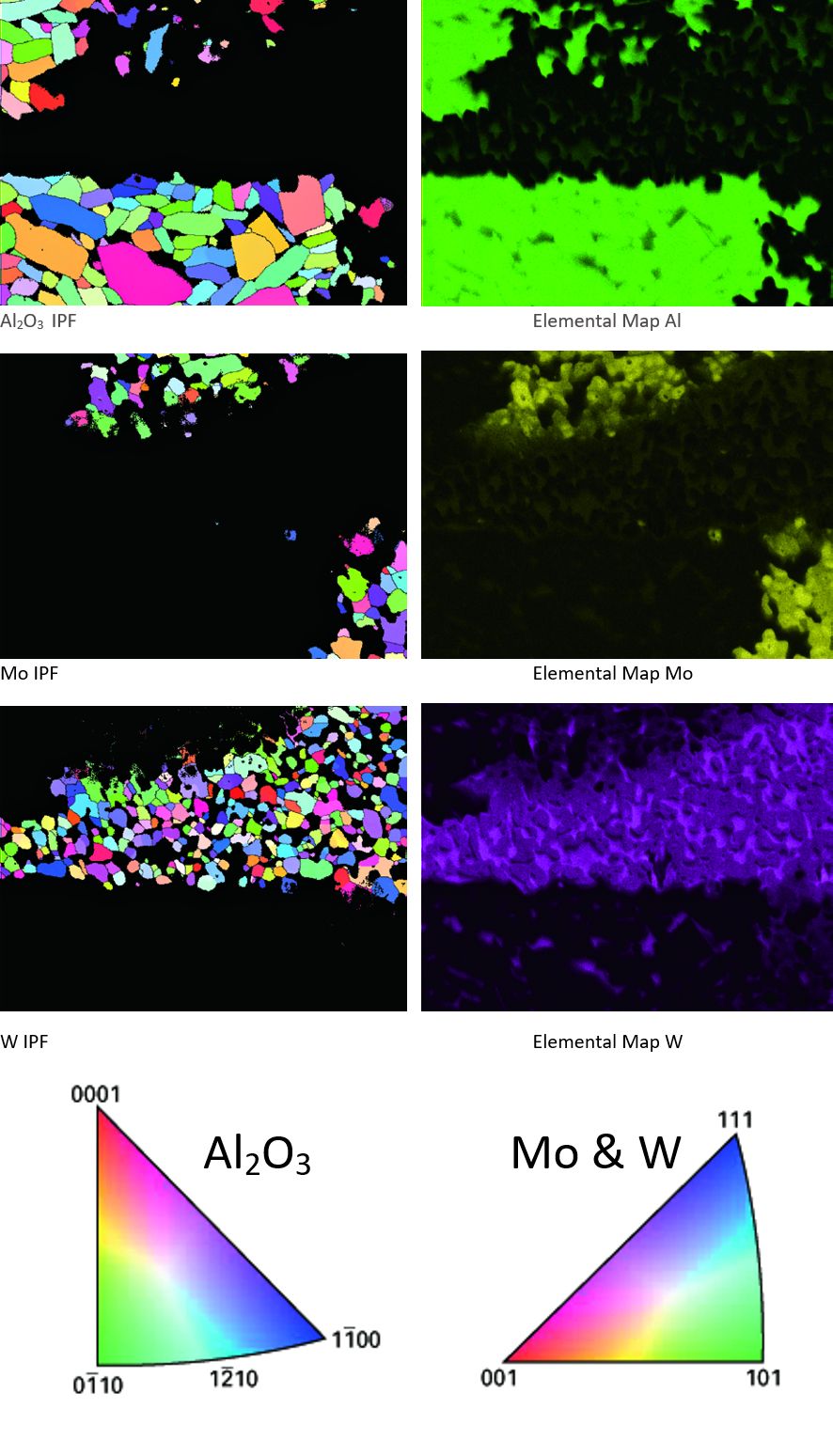

Texture and element mapping of metallic materials

Modern metallic materials are frequently formed of complex systems comprising various constituents. The spatial orientation of the individual crystals (texture) and chemical composition are important components with respect to the resulting mechanical properties. In order to be able to detect both the texture and the chemical composition in parallel, JEOL supplies powerful complete solutions from artifact-free sample preparation to comprehensive three-dimensional reconstruction. This enables the direct comparison of both analytical techniques.

Product groups

Preparation Systems

Solutions

Mulit-layered circuit on a ceramic substrate (Al2O3, Mo, W)

Mulit-layered circuit on a ceramic substrate (Al2O3, Mo, W)Mulit-layered circuit on a ceramic substrate (Al2O3, Mo, W)

Source: JEOL Ltd.